03.02.2021

Milling the Future

More productivity and flexibility in 5-axis simultaneous milling

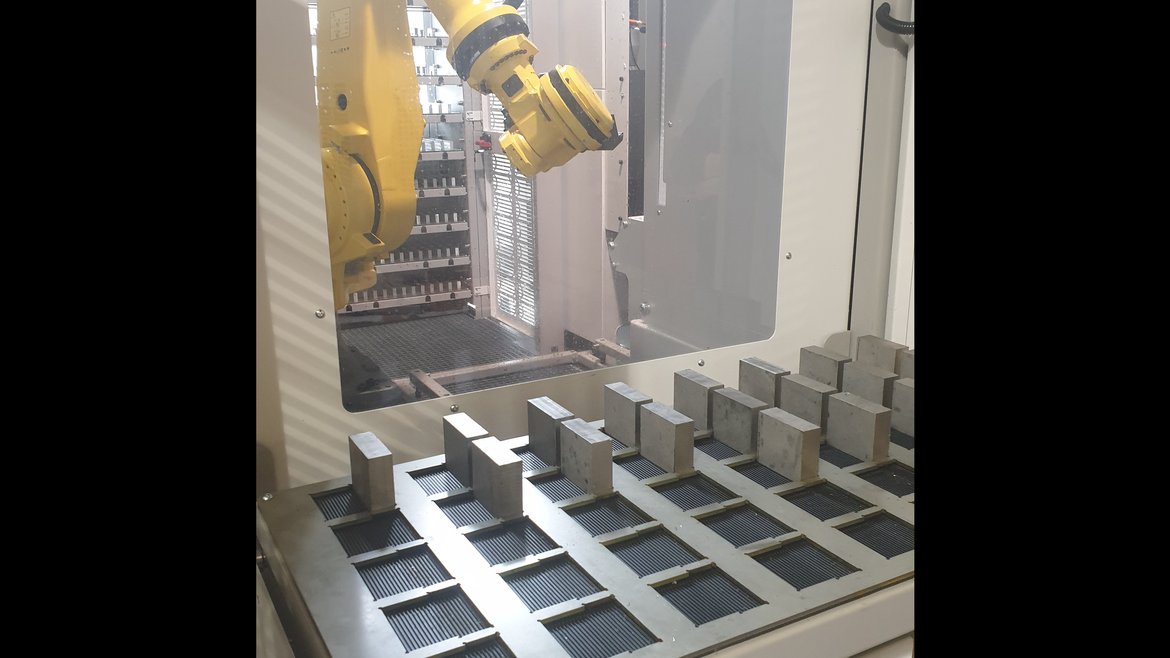

FAES-PWR ESTECH AG successfully commissioned a fully automated and highly flexible manufacturing cell with a capacity of 11'500 manufacturing hours / year in 2020.

The Board of Directors had approved the investment at the end of 2018. In spring 2020, the first machine and the automation could be put into operation. The commissioning of the second machine took place 2 months ago.

In the following article, we show the preparations for the investment decision and the subsequent implementation based on the most important keywords.

Initial situation

Forward strategy: Renewal of the machine park while simultaneously achieving competitive advantages through consistent expansion of automation in the area of 5-CNC axis milling. In detail this means:

- Parts handling combined with pallet handling

- Standardisation of tool holders (HSK-63A)

- Preventing investment backlog

- Increase / expand the degree of automation

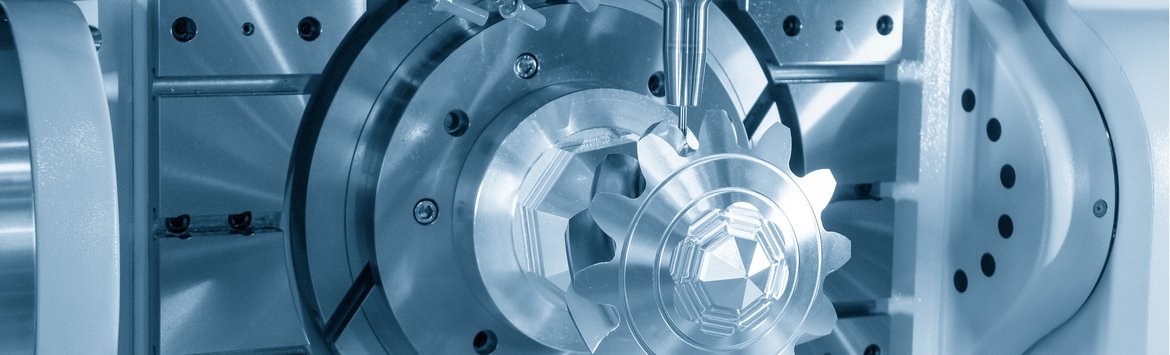

- Machining of all metals possible, such as aluminium, high-alloy steels, titanium and INOX

- Flexible production, short set-up times (pcs. 1 to 10'000)

- Standardisation of raw material handling / max.160x160x160 (robot)

- Speed 20'000 min-1, torque 100 Nm

Goals of the investment

Highly flexible and economical production of small batches from batch size 20 up to larger batches of 1000 and more.

- 7 days/24h operation, of which only 5 days operated over 2 shifts - remaining times fully automated

- Reduction of throughput times for large quantities or framework agreements

- Better planning (delivery reliability, procurement of raw materials)

- Replacement of 3 existing machines, thus increasing efficiency and reducing maintenance costs, efficiency increase of > 33%: 11'500 productive production hours with the same personnel resources

Solution

Excerpt from the specifications:

- 5-axis simultaneous milling with automation (robot).

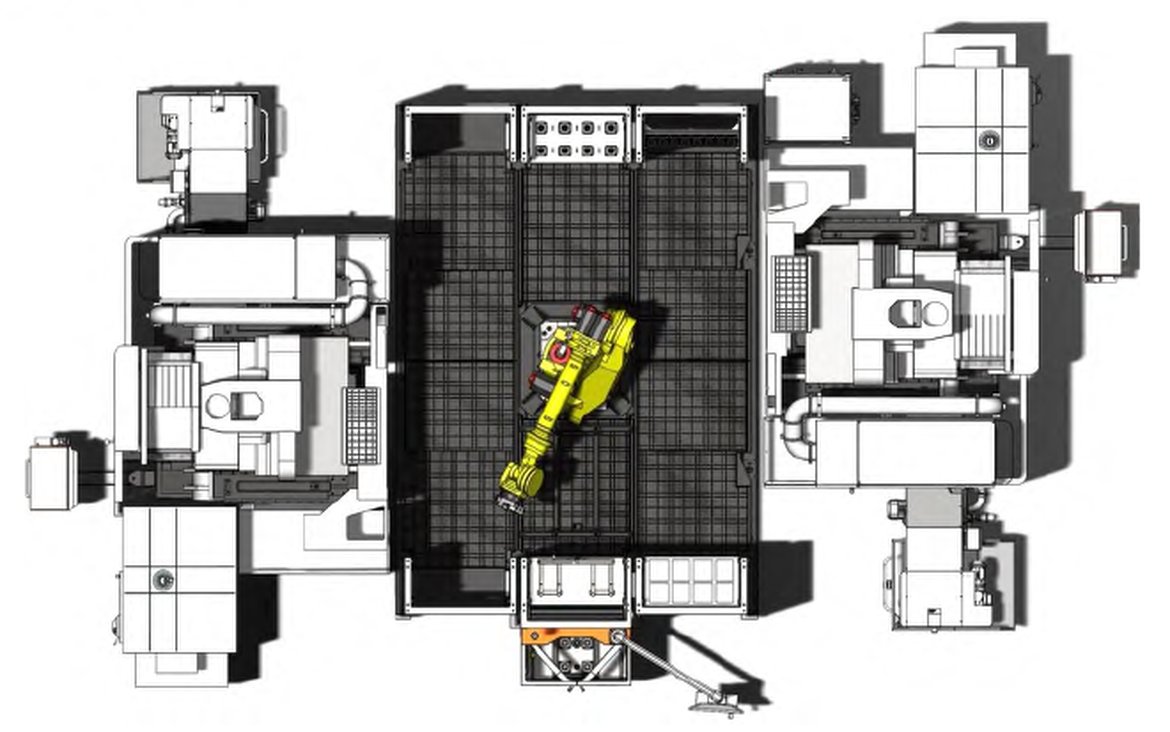

- Final configuration: two 5-axis CNC machining centres coupled to automation

- Machining of the workpieces in one set-up if possible

- Handling of pallets and raw materials

- 1st side / 2nd side fully automatic reclamping

SUCCESSFUL IMPLEMENTATION IN 2020

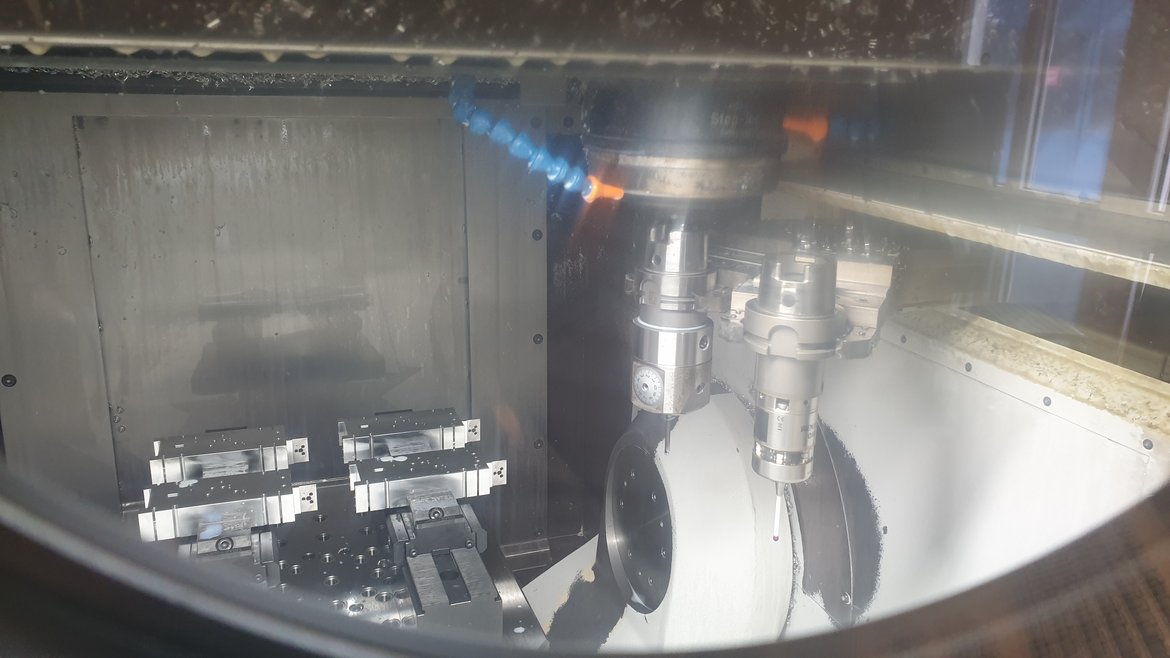

The decision was made to purchase two 5-axis GF-Mikron Mill P500U milling centres, which are loaded with an integrated robot handling system. The total investment amounted to around 1.9 million SFr.

The system has been in operation in 3-shift operation since autumn 2020. We will fully achieve the set targets by mid-2021. Highlights:

- The handling and supply of raw material to the plant by the robot functions completely autonomously over 7 days / 24 hours.

- The workpieces are reclamped fully automatically by the robot after machining in the first set-up and finished in the second set-up.

- All requirements for 24h operation over 7 days can be achieved.

- In fully automatic operation, the machining precision is ± 2μm.

Impressions