29.03.2019

Advantage through innovation!

When it comes to innovation, ESTECH Industries counts on cooperation with FHNW Windisch University of Applied Sciences and KTI Innosuisse

In the last months 2 projects were successfully completed. 1 main project, supported by the KTI Innosuisse, is still ongoing.

Digital production: Optimal, automatically calculated corrective measures in model-based mechanical production

Project of the FAES-PWR ESTECH AG and the Institute of Automation of the FHNW Windisch with the support of the KTI Innosuisse.

Starting position

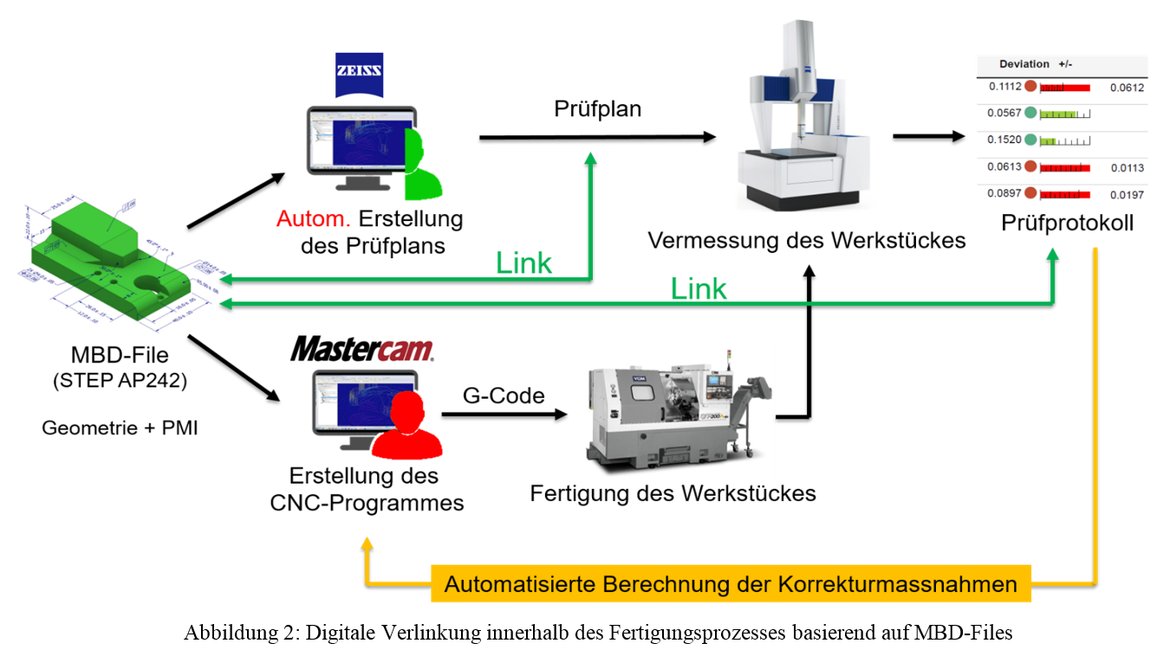

This time of time-consuming creation of 2D drawings is definitely over. They are replaced by MBD (Model-Based Definition) files, which provide digital information linked to 3D geometry and the attached quality requirements. This change closes the last digital gap in the manufacturing process and enables model-based production.

Project goal

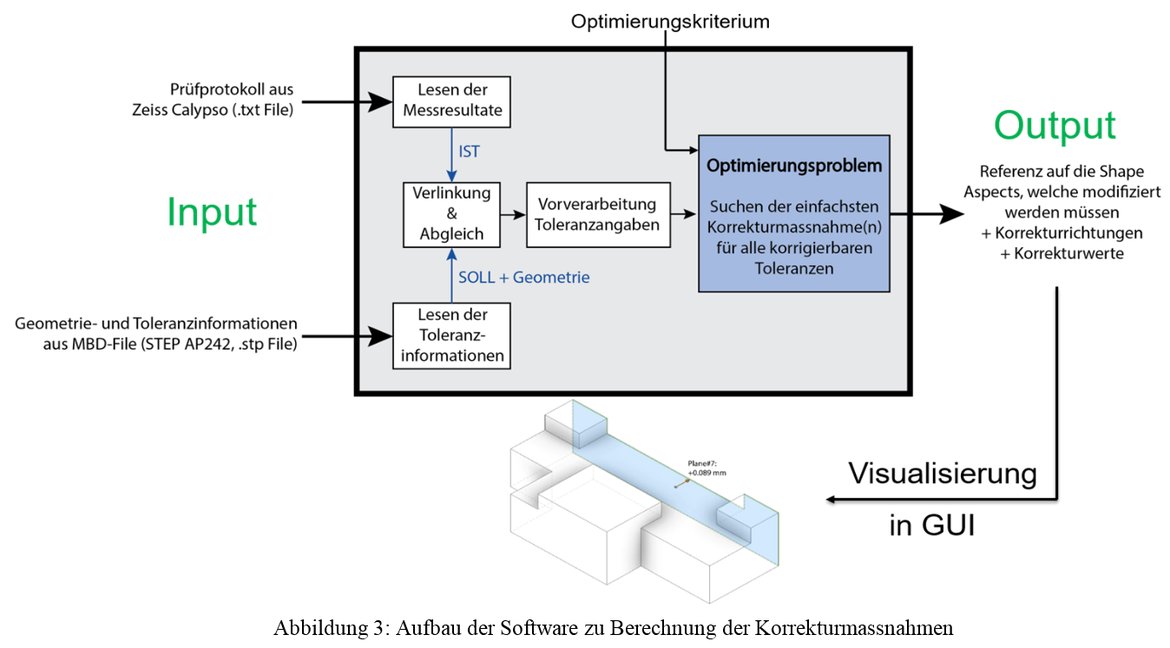

The aim is to develop an innovative, new algorithm for calculating the optimal correction measures of a workpiece made out of tolerance. This is intended to eliminate misunderstandings between the polymechanic and the measuring technician (mainly caused by inconsistent designations) as well as digitally described correction proposals. In a further step, these corrections can be implemented automatically in a CAM software and a self-regulating production process can be created.

Model-based mechanical manufacturing

Model-based mechanical manufacturing is, as the name already suggests, based on a virtual model. An MBD file such as the standardized and easy-to-read STEP AP242 format, which already exists since 2015, is used for this purpose. The resulting linkage between tolerances and the geometry of a workpiece results in unique designations for the 3D shape aspects and the attached PMIs (Product Manufacturing Information) throughout the manufacturing process. This creates digital dependencies between the MBD file, the test plan, and the measurement protocol, allowing optimal correction measures to be calculated for non-compliance with tolerance conditions.

Test measures which are outside the permitted tolerance must be identified, analyzed and processed to calculate an optimal correction. In addition, it should be checked whether in fact the test mass of a workpiece required by the customer has been measured or whether there are undesirable deviations of the geometric position or the tolerance value. These functions as well as the visualization of the optimal corrective measures are implemented in a new "correction tool".

Autlook

In a next step, the developed correction algorithm will be implemented as the main part of a specially developed correction tool, which should in future support the polymechanic in the implementation of corrective measures. The focus is always on the generation of digital links between all manufacturing and process sizes of the company, as this forms the basis of efficiency-enhancing digital production.

Opportunities in the field of electromobility

The aim of this project was to examine and develop the opportunities of ESTECH Industries in the field of electromobility. The projectteam consisted of 3 students of the Department of Energy and Environmental Engineering FHNW.

The analysis has shown that there are potential applications for ESTECH Industries in various electromobility areas.

Three fields of application were examined:

- Products with specific requirements

- Infrastructure and services

- Actors and potential partners

The analysis led to 3 main areas of innovation for which market access, sales potential and the necessary competencies were developed in a next step. The analysis of the three focal points led to an evaluation according to the defined criteria and finally to the recommendation for action.

Industrial consulting

The project was carried out by 3 students of the Department of Industrial Engineering FHNW. FHNW .

In the metalworking industry, billable consulting services are unusual until now.

Often, other potential cost advantages, such as cost savings, are not taken into account. alternative choice of material or design optimized according to manufacturing principles. Our sales professionals often point out these other potential cost benefits to customers as a non-fee-based advisory service aimed at better customer satisfaction. This consultation does not take place systematically and in each case individually dependent on the respective clerk. The customer is free to use the potentially possible cost advantages without any obligation that he must place the order for the production with us.

The aim of the project work was to check whether the consulting service (complete service package including supplementary services such as logistics, assembly, supplier network, TCO approach, etc.) can be provided in the future as a service to be paid.

The students developed a concept and a recommendation for action which were presented to the management on February 27, 2019.

In a first pilot project, valuable experience has already been gained, which is now being incorporated into the implementation.